Hydraulic systems are often utilized for various industrial equipment and firm machineries, including hydraulic torque wrench, industrial braking systems, and best hydraulic press machineries, among others. Hydraulic systems are also sensitive applications and are particularly affected by the build-up of excessive heat.

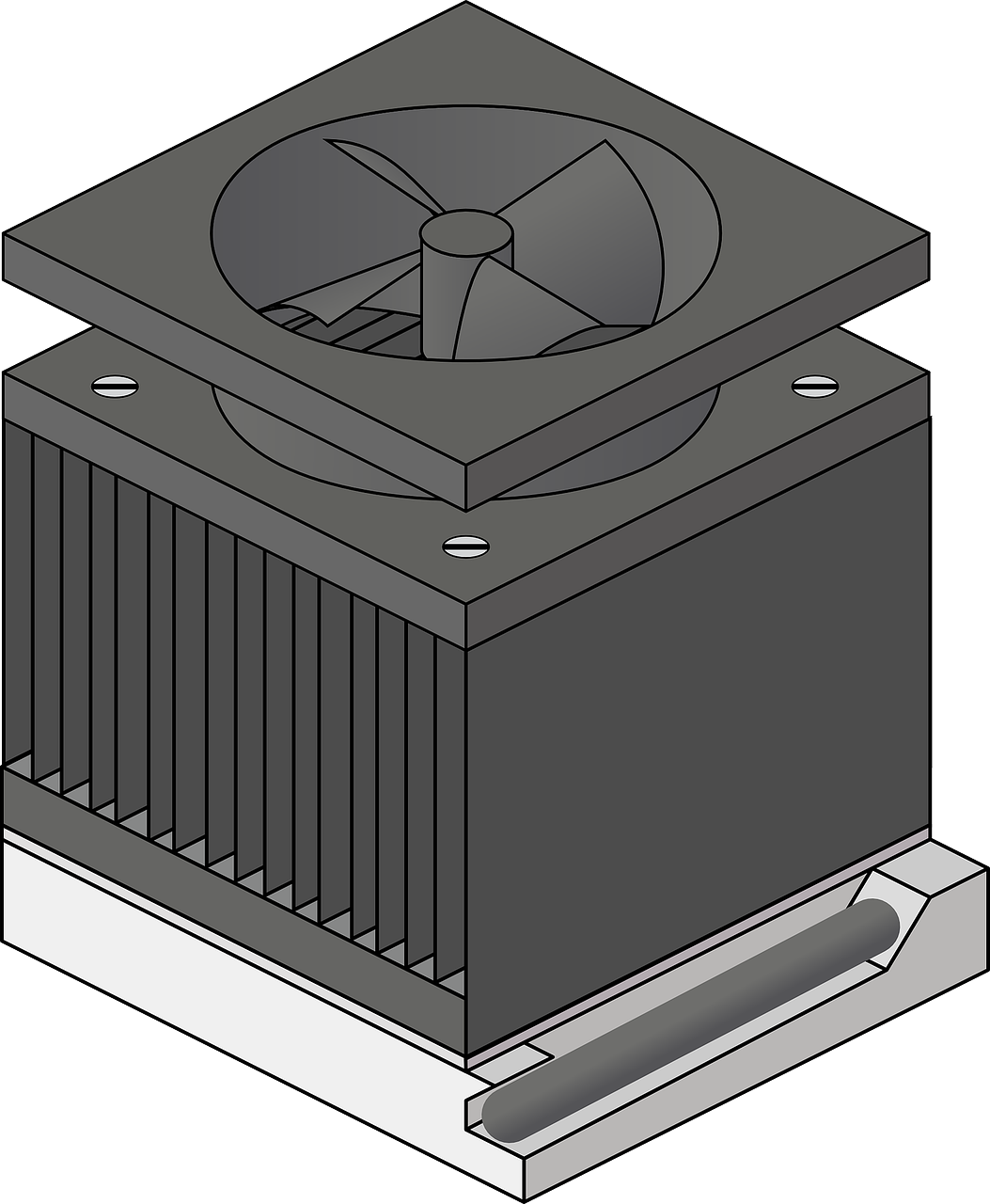

Here are some factors to consider when you investigate air coolers for Hydraulic Power Packs.

1. Large or Small System?

The larger your hydraulic power unit, the higher the chance it will need an air cooler. Smaller units can work with natural convection as they do not run at such high temperatures. Large units will most likely need an air cooler. You need to investigate the type of cooler that matches your requirements in terms of industrial processes and applications.

2. Environmental Considerations

The environment in which your hydraulic power pack is located affects the operation of the system. Units located in hot climates or areas exposed to the elements will have to work harder than systems installed in a more stable environment. The more a system works, the more cooling required. Therefore, a larger air cooler is needed to correctly regulate the system’s temperature. However, installations in cooler climates don’t need as much cooling (as you would expect.) A smaller air cooler will suffice in these situations.

3. Looking Into Temperature Cycles

It is also important to work with the temperature cycles of the system. Machines may operate at higher temperatures when using a long cycle, which will need to be factored in when deciding on which air cooler to fit. Look at the timescale of the changes in temperature to work out the best fit for a particular unit.

4. Space Needed and Available

Look at the amount of space you need to fit an air cooler at the planning stages of installing and running a hydraulic power system. The space needed varies greatly for different units. Some are more complex than others. Bespoke systems and those with extra attachments may require more space for fitting an air cooler. It is imperative that you look at these considerations right at the start so that you don’t run out of room for this essential component.

Choosing a hydraulic power unit system is a complex task. There are many factors to consider, and an air cooler is just one of the essential components for a fully functioning and reliable machine. Be sure to consider all your options when selecting your system and deciding where it will be located. Professional advice is useful in the early stages of your hydraulic power unit planning since mistakes can be more easily rectified during this time. With a wide variety of systems and components available, take your time to make the most effective choice for your business and industrial applications.

Leave a Reply