In the realm of material processing, the evolution of technology has led to significant advancements, particularly in the area of material mixing. Among these developments, twin screw extruders and compounding machines stand out for their efficiency, versatility, and the quality of the output they produce. This article delves into the sophisticated world of these machines, exploring how they are revolutionizing material mixing processes in various industries.

The Mechanics of Twin Screw Extruders

Twin screw extruders are at the heart of modern material mixing techniques. These machines consist of two intermeshing screws mounted on parallel shafts within a closed barrel. As the screws rotate, they transport, mix, and cook materials, offering a high level of control over the mixing process. This control is crucial for producing a homogeneous mixture, especially when dealing with complex materials or formulations.

Versatility and Precision in Compounding

Compounding machines, particularly those equipped with twin screw extruders, are known for their versatility. They can handle various materials, from plastics and rubbers to food and pharmaceuticals. The precision with which these machines operate allows for incorporating various additives, fillers, and reinforcements, enabling the creation of custom-tailored materials with specific properties.

Enhanced Mixing Capabilities

One of the key advantages of twin screw extruders in compounding is their enhanced mixing capabilities. The design of the screws and the barrel can be modified to suit different types of materials and mixing requirements. This adaptability ensures efficient and thorough mixing, which is critical in achieving the desired material characteristics.

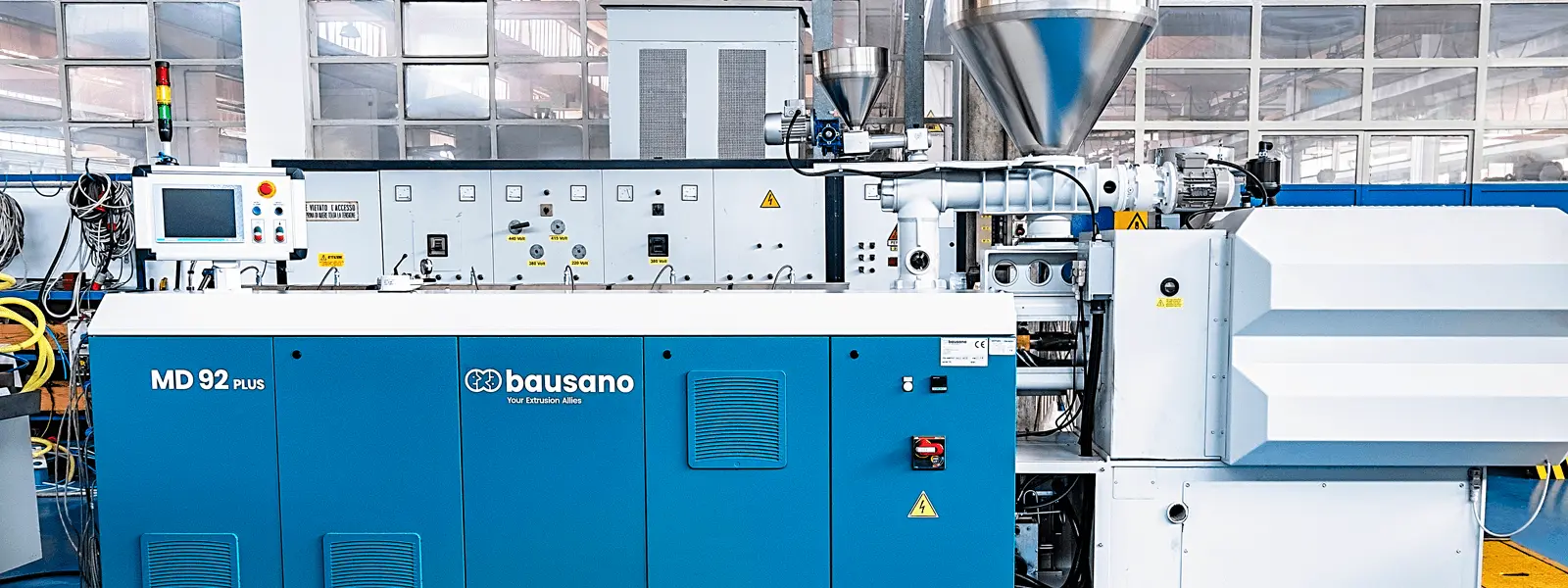

Advancing Extrusion Technology

Bausano, a leader in designing and manufacturing extrusion and compounding equipment, has been instrumental in advancing these technologies. The company’s twin screw extruders and compounding machines are known for their high quality, efficiency, and innovation. Bausano’s commitment to research and development has resulted in machines that are not only highly effective but also user-friendly and energy-efficient.

Energy Efficiency and Sustainability

In today’s environmentally conscious world, energy efficiency and sustainability are paramount. Twin screw extruders and compounding machines are being designed to minimize energy consumption while maximizing output. This approach not only reduces operational costs but also aligns with global efforts to reduce the carbon footprint of industrial processes.

Customization and Flexibility

Another significant aspect of modern twin screw extruders and compounding machines is their customization and flexibility. Manufacturers like Bausano understand that each material mixing requirement is unique. Their machines are therefore designed to be highly customizable, with adjustable parameters such as temperature, screw speed, and feed rate to accommodate a wide range of materials and applications.

Future Trends in Material Mixing

Looking ahead, the future of material mixing with twin screw extruders and compounding machines appears bright. Continuous advancements in screw design, process control, and automation are expected to enhance the capabilities of these machines further. Integrating smart technologies and IoT (Internet of Things) is also anticipated, leading to more efficient, precise, and intelligent material mixing solutions.

Conclusion

Twin screw extruders and compounding machines represent the pinnacle of modern material mixing technology. Their ability to handle diverse materials with precision and efficiency makes them indispensable in various industries.

As the demand for more sophisticated and sustainable material mixing solutions grows, the role of twin screw extruders and compounding machines will undoubtedly become more significant, driving the future of material processing towards new heights of innovation and efficiency.

Leave a Reply